Central heating problems – faulty zone valves

So, another week and another problem presents itself at the DIYite Cottage – this time, in the form of a malfunctioning central heating system. It just dawned on us after a couple of slightly chilly days in the house, that the heating wasn’t coming on properly.

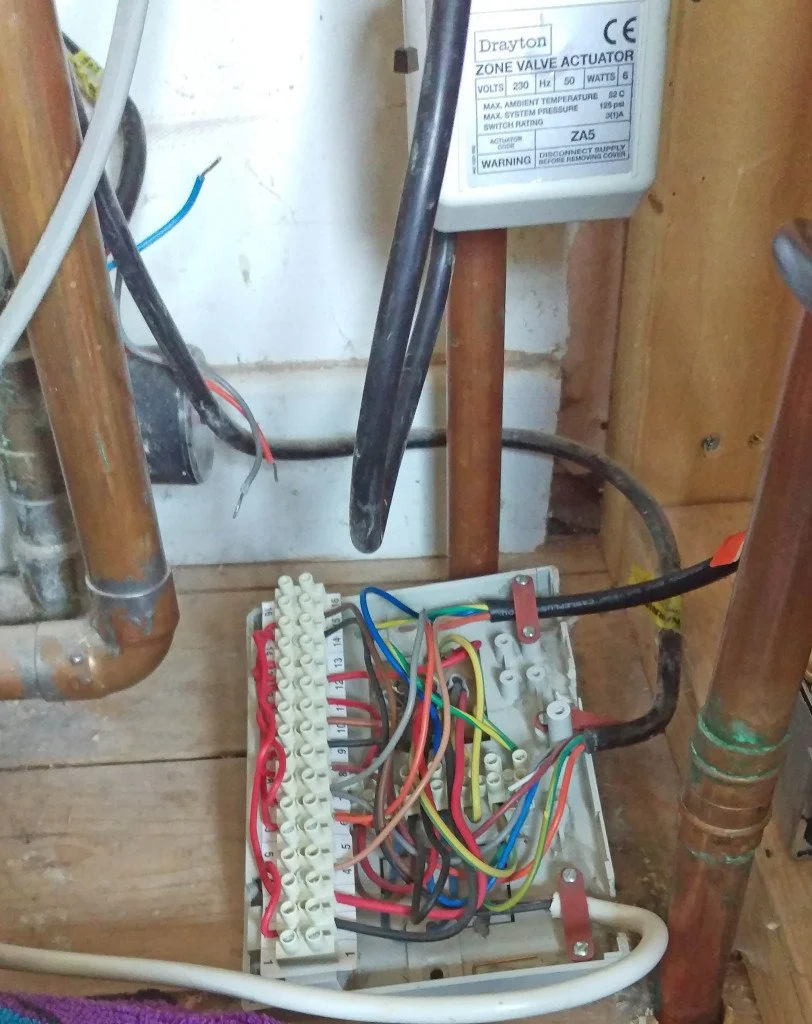

The offending Drayton Zone Valve Actuators – now removed

And this was doubly confusing because the hot water was functioning fine.

I should explain we’ve got a Worcester Bosch oil system boiler that heats the hot water and separately, the central heating system. We’ve got a Drayton dial room thermostat and a Drayton Lifestyle LP241 programmer (the company that installed my central heating system was clearly a fan of Drayton products)! So when I pressed the Hot Water button on the programmer there was a reassuring click followed by the distant hum of the boiler firing into action. When I did the same with the Heating button, nothing happened.

The fact that the hot water was working led me to conclude (with my still rather patchy knowledge of boiler operations!) that the boiler was fine. A quick call to the Worcester Bosch sort of confirmed this. So I (wishfully thinking) decided it must be the dial thermostat, and so popped out to Plumb Centre to buy a new one – unfortunately that didn’t fix the problem.

My attention then turned to the Zone Valve Actuators – motorised valves that open and close depending on whether I’ve asked the boiler to provide heating or hot water. The trouble was that when I got my wife to alternately click on the Hot Water and then Heating, each valve whirred reassuringly into action, which made me a bit dubious that these could be faulty.

In a quandary I contacted my boiler service engineer to see if he could shed any light on the problem. Based on what I told him he said he thought it was almost certainly these zone valve actuators that were faulty. When I told him they were Drayton he said he was always having problems with faulty Drayton zone valves (sorry Drayton, I’m just repeating what he said!) So he suggested I replace both actuators with Honeywell V4043 zone valves. At well over £100 for the pair, this was a bit of a punt, but I took his advice and when to Plumb Base (this time!) a few days later to pick up the new zone valves and some inhibitor (which he suggested I put into the system whilst I was replacing the valves.

Yikes! I was operating pretty far out of my comfort zone on this one, but luckily I have fairly recently replaced our bathroom single handed, and in so doing, learnt quite a lot about plumbing on one hand, and the intricacies of draining down our central heating system on the other.

With the faulty Zone Valve Actuator still in position on the heating pipe (back right, top), I set about wiring in the new Honeywell zone valves

The first job was to drain the pressurised central heating system. This is less complicated than you would think, and is simply a matter of connecting a hose pipe to the outlet valve on the radiator located nearest the back door, and then opening up the bleed valves on the (in my case upstairs radiators). The water in the radiators and connecting pipes then simply flows out through the hose pipe.

With all power switched off, and the central heating system drained, I then set about connecting up the new zone valves. As you can see, the junction box for the central heating system is a bit of a perplexing spaghetti junction, but by disconnecting each wire of the faulty actuator valve one by one, and then connecting up the corresponding wire for the new Honeywell zone valve (they’re all colour coded) I was able to do this without too much trouble.

Then it was time to get my plumbing hat back on, and replace each zone valve. To do this, I had to loosen the nuts on the zone valve compression joints, with a spanner clamped behind the valve to take the strain as I loosened each nut. Removing each valve was a little tricky as the 22mm diameter copper pipework that supplies water through the valve is slotted into each valve. Luckily there was just enough play in the pipes for me to manipulate the faulty valve off the pipework. I cleaned up the end of each pipe with some wire wool, and poured the new bottle of inhibitor I had bought into the empty pipes before slotted the new valves into place.

I then applied some Fernox jointing compound (also left over from my previous plumbing exploits) to the olives on the pipework before tightening the nuts back into place on the new valves. It’s a bit of an acquired art to know how tight to go with the nuts, and something experience helps with, but you basically keep tightening until the nut just stops moving. You don’t want to over-tighten a compression joint, but you want it to be reassuringly tight.

A few points to make here. The first is that in plumbing in the new valves it’s important not to grip the valve head (basically the metal case that contains the motor and electrics). You have to attach a spanner onto the valve body at each port whilst tightening up the nuts. The second is that I found it helped to move the manual lever on the valve head casing from ‘AUTO’ to ‘MANUAL’ as this kept it out of the way of the spanner I was using to tighten the nuts – which I was worried might otherwise damage the lever.

Thirdly, whilst the Drayton zone valves had to be positioned with the flow direction in through ‘Port A’ and out through ‘Port B’ – which basically meant the hot water zone valve was upside down and the heating zone valve the right way up, it’s not critical which direction the Honeywell zone valves are positioned. The only important thing to observe is that the valve must not be mounted so that the valve head (the metal box you can see below with the danger sign on it) is below the horizontal level of the pipework, as in the unlikely event of a leak, a safety hazard could result.

The new Honeywell Zone Valves now in position.

So with all that done, it was simply a matter of refilling the heating system – as to how to do which, you might like to check out my earlier blog on how to bleed a radiator. Then I moved the manual lever on each valve head back to ‘AUTO’, switched the power back on, set the dial thermostat to maximum.

With baited breath I then pressed the Heating button on the programmer…. and then after a few silent moments, relief as I heard the reassuring sound of the boiler firing into life. Hallelujah! Job done, and I have to say, an enormous sense of satisfaction at having solved a problem that a few days earlier had me scratching my head in confusion.